Exploring the Types of Dexterous Robotic Hands on the Market

Dexterous robotic hands are revolutionizing automation, research, and various industries by replicating the intricate capabilities of the human hand. Designed for everything from surgical assistance to complex manufacturing, these advanced robotic hands vary in functionality, material, and application. This article explores the primary types of dexterous hands available on the market, helping you choose the best fit for your needs.

1. Industrial Dexterous Hands

Industrial dexterous hands are engineered for heavy-duty tasks in manufacturing, assembly, and packaging. Built with strength and durability in mind, these hands typically feature metal and high-strength composite materials that can handle repetitive motions and large workloads. They’re often designed to manipulate objects of various shapes and sizes with high precision and can be found in sectors like automotive, electronics, and consumer goods manufacturing.

Best Suited For: High-precision tasks in manufacturing, assembly lines, and industrial automation.

2. Medical Dexterous Hands

In healthcare, robotic hands have been developed to assist with precise, delicate tasks, such as surgical operations. Medical dexterous hands are often used in minimally invasive procedures, offering surgeons the ability to make extremely fine movements with robotic assistance. These robotic hands need a high degree of flexibility and precision, so they are typically designed with soft, articulated joints that mimic human dexterity closely.

Best Suited For: Surgical applications, patient care, and medical training environments.

3. Research Dexterous Hands

Research-focused dexterous hands are created for academic and experimental purposes, allowing researchers to explore robotics, AI, and machine learning applications. These hands often come with advanced sensors, flexible grips, and modular designs to adapt to various tasks. Research dexterous hands are used in labs to experiment with complex tasks like grasping, manipulation, and tactile sensing.

Best Suited For: Robotics and AI research, educational institutions, and experimental applications.

4. Soft Robotic Dexterous Hands

Soft robotic hands are built with flexible materials such as silicone, allowing for a gentler touch. Unlike rigid designs, soft robotic hands are ideal for handling delicate objects without causing damage. They’re commonly used in industries that handle fragile items, such as food processing or lab work. These hands replicate the compliance and flexibility of the human hand, making them effective in handling objects that vary in shape and fragility.

Best Suited For: Food processing, laboratory handling, and applications requiring a gentle touch.

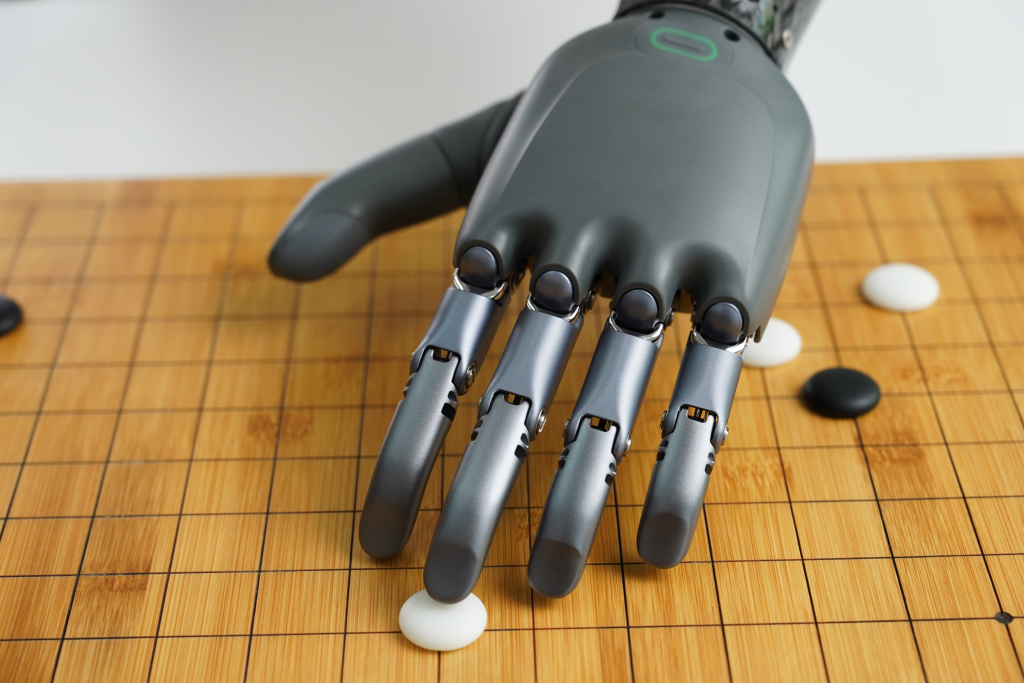

5. Anthropomorphic Dexterous Hands

Anthropomorphic hands are designed to mimic the appearance and function of human hands as closely as possible. They are typically used in applications where naturalistic interaction with humans is essential, such as in social robots or human-robot interaction studies. These hands are often equipped with high-fidelity movement capabilities, jointed fingers, and skin-like material, making them a popular choice for fields such as prosthetics, robotics research, and interactive displays.

Best Suited For: Social robotics, prosthetics, and applications requiring human-like interactions.

6. Tactile Dexterous Hands

Tactile robotic hands are equipped with sensors that provide feedback on pressure, texture, and other sensory details. These hands allow for a high level of control and adaptability, making them ideal for applications where feedback is essential to determine grip strength or object properties. Tactile dexterous hands are often employed in research and tasks where environmental awareness is required, helping to advance developments in AI and machine learning for robotic applications.

Best Suited For: Research, AI development, and applications that require sensory feedback.

7. Adaptive Gripping Dexterous Hands

Adaptive gripping hands are designed for applications where objects vary widely in shape and size. They adjust their grip based on the object’s dimensions, making them highly versatile in environments like warehouses and logistics centers. These hands are often paired with AI to identify the best grip method, allowing them to handle objects in dynamic or unpredictable settings.

Best Suited For: Logistics, warehousing, and environments requiring flexible handling of various items.

Choosing the Right Dexterous Hand for Your Needs

Dexterous robotic hands come in numerous forms, each tailored for specific tasks and environments. Whether you need precision for industrial manufacturing or flexibility for research applications, there’s a robotic hand designed to meet your requirements. Each type of hand leverages different materials, mechanics, and technologies to achieve the unique needs of industries ranging from healthcare to logistics.

For more information on the latest advancements in dexterous hands and how they can enhance your projects, visit Oceantrix.com. Oceantrix offers a range of high-quality robotic hands designed to improve efficiency, precision, and adaptability across various applications.

Learn More about Dexterous Hand

OceanTrix is an factory produce robotic dexterous hands. We are here to speed up your project.